SUE – The Future of Locating Buried Utilities Is Now

Investigating the underground world and depicting the findings has become a significant challenge as an ever-increasing plethora of utility infrastructure continues to age. As more utilities are installed in the ground, it is integral to identify and record information as it relates to gas, fiber, water, telecommunications, sewer and electric utilities to protect them and ensure the safety of field crews and private citizens.

The Science Behind Locators

Some buried utilities emit a passive charge or transmit a signal, similar to radio stations. Locator tools have the ability to tune to these frequencies and pick up the signal that is produced. However, some lines do not give off a passive signal. In these cases, a transmitter can actively induce a signal onto a conductive line, allowing the locator tool to receive the signal.

Active locating is searching for a targeted utility by means of direct connection to the conductive utility or inducing a frequency onto it. The transmitting equipment is either attached directly to the line or, if you cannot make a direct connection to the line, a frequency is selected and induced into the ground and reradiated by the targeted utility.

If a designating technician is actively locating utilities, there are multiple methods in which to introduce signal to the targeted utility:

Direct connection: The most common connection method in the industry. This method uses direct connection leads, much like jumper cables, with positive and negative polarity to introduce alternating current along the utility.

Induction: There may not always be direct access or safe methods to creating a direct connection. Contractors may also utilize an inductive ring clamp that allows them the ability to focus the induction of the signal more directly onto the targeted utility. Alternatively, a contractor can induce a single high frequency by pushing a signal from a transmitter through the earth’s surface to a conductor buried below that then radiates the signal back to a receiver. This method tends to work well on lines and pipes in non-congested areas, but introducing a high frequency into the ground can often produce a distorted signal in areas where multiple utilities are housed.

Passive locating is commonly used to check project areas for unknown buried utilities. A contractor can simply use a receiver to sweep the area, looking for frequencies that are radiated and re-radiated naturally. This method does not allow the operator of the locating equipment to distinguish between the types of buried utilities; it only provides an indication of the possible presence of a utility.

Locating Tools

The industry utilizes two types of locating tools: single- and multiple-frequency to accomplish active and passive locating. There are strengths and limitations to each.

The single-frequency tools have been used for decades. These systems consist of a transmitter and a receiver that are tuned to a specific frequency. Although these units have the ability to directly connect and induce a signal via ring clamp coupling, they are widely used to induce through the ground.

Multiple-frequency tools allow you to tune the frequency higher or lower to better locate the different materials involved in constructing the utilities. The lower frequencies tend to travel effectively along the targeted utility, while higher frequencies may become distorted and bleed off to non-targeted utilities.

Technology Enhancements

While the technology of locating equipment has not drastically changed in the past five to seven years, many manufacturers are adding enhancements such as Bluetooth communication and GPS integration to provide better signals and to attach the locations to GPS coordinates.

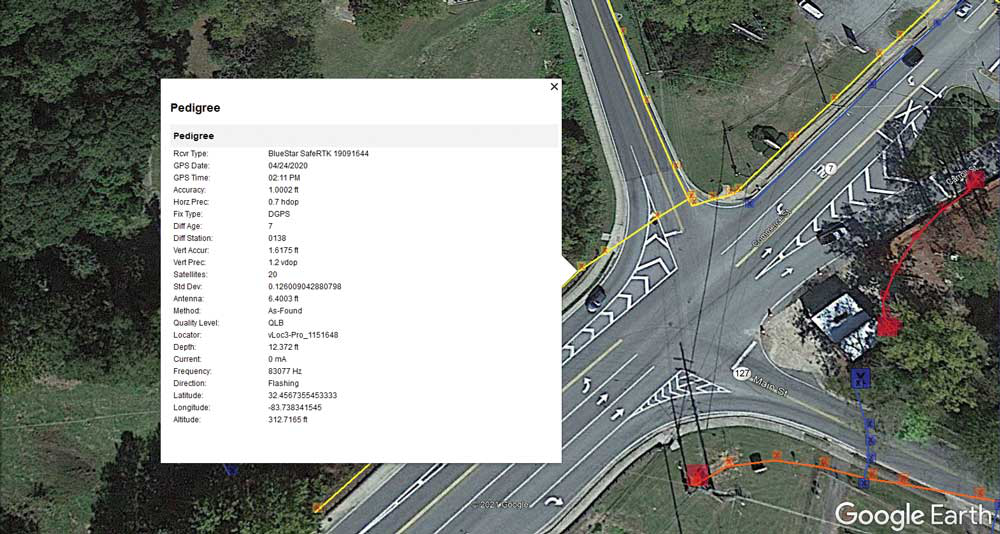

Nearly all manufacturers are increasing the power of their locating transmitters to achieve clearer and more quality signals. There have been advancements to the receivers to help filter out the unwanted noise and bleed-off that assist in gathering a more accurate signal and reading. The industry is also coupling the locator receiver with GPS devices, external or internal, that allow mapping of the utility line with increasingly more accurate latitude and longitude coordinates.

Damages to underground infrastructure have reached unacceptable levels. Current industry practices to determine the location of buried infrastructure utilize antiquated business methodology, including paper documentation, paint, or flag markings, some of which have proven ineffective in creating a dynamic database of this critical information. In the U.S. alone, we spend approximately 10 billion dollars a year locating underground utilities, and yet we still have an annual impact of 30 billion on the economy and, ultimately, the customer’s utility fees.

To combat this issue, software has been created to leverage new technological enhancements. According to Matthew Breman, vice president of marketing at ProStar GeoCorp, this software is “designed to improve any industry’s business operations that require knowledge of the precise location of sub-surface infrastructure. By providing real-time access to precise location information, [the software] eliminates and streamlines outdated workflow processes and legacy equipment to deliver mission critical data in real-time to all field and office personnel.”

The software “is a patented mobile and cloud application that seamlessly connects the field with the office and provides the ability to precisely capture, record, and display, critical infrastructure data necessary for the efficient and timely maintenance and management of surface infrastructure including roads, bridges, railways, pipelines, and subsurface infrastructure including utilities and pipelines from a standard mobile device,” shares Breman.

Leveraging Technology

Breman also states that “quantifiable research on completed large infrastructure projects shows that using cloud and mobile capabilities have reduced utility line strikes by over 90 percent, reducing risk to workers, the environment, and the public while creating considerable cost savings.”

Integrating a software such as this allows for more efficient workflows and more accurate systems of record for the vast array of buried utilities. Locating companies are able to more effectively and efficiently implement a more direct and stringent quality assurance/quality control (QA/QC) program that is advanced and cutting-edge. These efficiencies can equate to increased savings and profit while minimizing construction delays and change orders.