TRACTO-TECHNIK usesinnovation for last mile

高性能光纤网络是数字化众所周知的主干。在工业化国家/地区,网络扩展正在迅速发展,但是在许多地方,从分销商到最终客户的快速Internet连接是阻碍扩展速度的瓶颈。在这些地方,使用了非开挖的非转向土壤置换锤。在钻孔路径中,可用空间或地形的复杂性要求钻孔是可操纵的,因此,微型流体辅助钻井系统是首选。

TRACTO-TECHNIKhas introduced a new mini HDD rig for near-surface installations, addinganother dimension to an already impressive range.

High-performance fibre optic networks arethe proverbial

backbone of digitisation. Network expansion is progressingrapidly in the

industrialised countries, but the connection of the fast internetfrom the

distributor to the end customer in many places is a bottleneck slowingdown

expansion.

In these places, trenchless non-steerablesoil displacement

hammers are used. In the bore path, the space available orthe complexity of the

terrain require the bore to be steerable, minifluid-assisted drilling systems

are the means of choice.

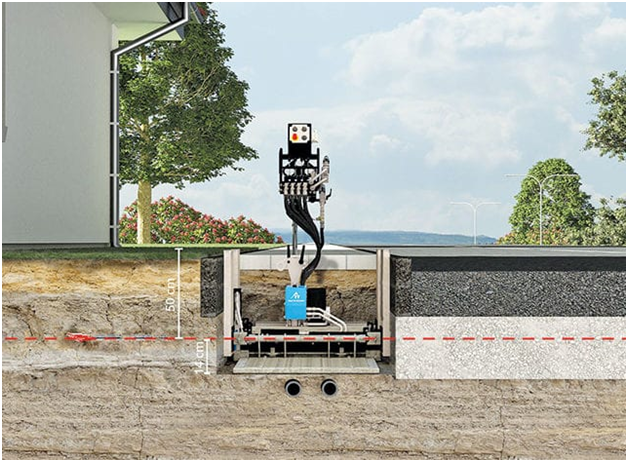

The compact

equipment in the smallestspace: the only 1 m wide starting pit for the

GRUNDOPIT PS40 fits exactly intothe pavement.

Minimallyinvasive

and speedy bores

The GRUNDOPIT PS40 is the latest additionto the series of

mini HDD rigs available from TRACTO-TECHNIK, which includesanother pit-launch

system, model PS60, and the KS50 keyhole rig for works fromout of a circular

construction pit. The new GRUNDOPIT PS40 was developed inview of the need for a

more compact mini drilling rig with even less spacerequirement for the speedy,

near-surface installation of fibre optic houseconnections.

Thus, the GRUNDOPIT PS40 requires only a 1m wide starting

pit that fits into pavement, making it ideal for the productionof fibre to the

home (FTTH) connections directly from the pavement, under whichthe public fibre

optics infrastructure normally runs.

Due to the low distance between the boreaxis and the

bottom of the starting pit, the bores can be carried out directlyabove the

existing underground infrastructure from out of a flat starting pit.That way

service lines for fibre optics and all kinds of media, such as waterand gas,

are established quickly with little effort and minimal surfacedisruption.

GRUNDOPIT PS40stands the official test

After an extensive internal testing phasethe GRUNNDOPIT PS40 stood its first official test in Spring 2020 onsite at aGerman nationwide broadband expansion project. Here, the civil engineeringcompany Helmut Lübben Fernmeldebau GmbH began the third of eight constructionphases of the government-funded project in the Upper Bergisch region ofGermany.

It successively installed the fibre opticcables along the road and, as requested, also produced the house connections.The latter was also due for the two semi-detached houses in the narrow but busyMarienheider Street – two landlords were eagerly waiting for “fast internet”and also for the installation of their house connections.

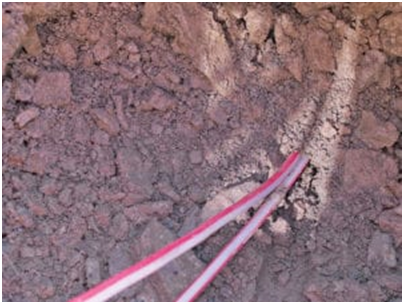

At this house, the steerability of thedrill head was required for the construction of the house connection (30 mlength for two x PE speed pipes with OD 12 mm) due to the bore path. Directlyat the narrow edge strip road/border front garden of the house, under which thefibre optic infrastructure is located, the flat starting pit with dimensions ofonly 1 m x 1.2 m and the target pit with approximately the same dimensionsdirectly at the house were dug out quickly.

The two PE speed

pipes OD 12 are pulledinto the bore channel during retraction with the fibre

optic cables laterpulled into the so-called speed pipes.

Easy job forthe

little high-flyer

After stably and quickly clamping andadjusting the

GRUNDOPIT PS40 on the hydraulic pit starting frame with theside-mounted work

plate in the starting pit, the distance of only 14 cm betweenthe drilling axis

and the pit floor – which allows drilling

directly above theexisting pipeline network – was

clearly visible.

The rod magazine for the 30 m longfluid-assisted bore was

within easy reach, the drive unit within sight. Thedrill rod coupling on the

rotary drive is also fast and productive thanks to aquick-release drill rod

connection.

One rod after the other “disappeared” intothe bore

channel. After just under an hour – interrupted only by

a fewdirectional corrections – the pilot bore reached

its destination. Company ownerHelmut Lübben was

thrilled when, after 30 m, the drill head emerges in thetarget pit.

“I was a little sceptical, but the actualprecision landing of the

drill head in the target pit convinced me and I amimpressed,” he says.

Then, the PE speed pipes OD 12 mm wereswiftly pulled into

the pilot bore hole while the rods were being retracted.The house connection

was optimally prepared for blowing in or pulling in thefibre optic cables at a

later stage and the two landlords were surprised thiswas done so quickly,

easily and, apart from a few footprints in the frontgarden, without any damage

to the meadow.